PRODUCT & SERVICES

Showing 7–12 of 31 results

-

Sand, Activated Carbon, Multimedia and Greensand Media – choice of a filter depends upon the quality and source of water. Ideally for river water filters are placed after clarifier. For deep well water, as the suspended solids are much lesser compared to river water one can design system with filters as pre – treatment without clarifiers. Sand Filter and multi media filter are used for removing traces of TSS while activated carbon filter is used to remove color and organics. Green sand media filter is chosen when Fe and Mn are higher in the raw water.

Filters

-

![hotwater[1]](https://www.southchem-group.com/wp-content/uploads/hotwater1.jpg)

Hot Water Clarifiers – ships, vessels and barges normally require hot water Calorifiers for producing hot water for domestic applications & bathing. We have a wide range of HWC with different heat input like electrical or fuel oil based.

Hot Water Clarifiers

-

Industrial Maintenance / Cleaner

No.

NASCO Products

Classification

Function

NOTE

1

NASCO CL 209

Crystalline acid cleaner

To remove silica scale deposits from boilers and heat exchangers.

2

NASCO CL 207P

Mill scale and grease cleaner

To remove oil, grease, pipe joint compounds or other foreign matter which may have been left during fabrication.

Boiler boil out

3

NASCO CL 207 H

Liquid acid cleaner

To remove scale, corrosion and other water deposit in boiler, compressor, condenser, heat exchanger and other equipments.

For used in boilers and heat exchangers

4

NASCO CL 206

Aluminum coil cleaner

To removes a dulling oxide layer on aluminum surface and as heavy duty cleaning for tough coil problems

For used in air conditioner, etc

5

NASCO CL 205RC

Resin cleaner

Using for cleaning sodium zeolite softeners which may have become fouled by iron, silt or turbidity

6

NASCO 130

Biological treatment for wastewater

Grease trap and pipe cleaner odor control for aerated, septic tank treated lagoon, septic tank treated

Blend of various bacteria

7

NASCO 120

Scale and corrosion inhibitor

An effective scale and corrosion inhibitor for once through water system

Film forming polyphosphate

8

NASCO FOT 110

Fuel oil additive

To eliminate sediment and sludge in fuel tanks

Improve fuel efficiency

9

NASCO CL 207S

Rust and scale remover

An efficient remover of rust, scale, corrosion products and passivate at the same time for base metals and other mixed metals without attacking the metal surfaces

Compatible with stainless steel

10

NASCO 623

Cationic polyelectrolyte

Use as a coagulant and coagulant aid

For water clarification

11

NASCO 823

Alkaline neutralizing compound

Use as a powerful neutralizing agent

Used after acid clean

12

NASCO 208

Scale and alkalinity control

To control scale and alkalinity in cooling water, recommended to use when the cooling water is became highly alkaline

Reduced alkalinity thereby prevents scale formation.

Industrial Maintenance / Cleaner

-

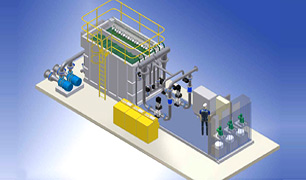

The membrane bioreactor (MBR) is the combination of a membrane process like micro filtration or Ultra Filtration with a suspended growth bioreactor, and is now widely used for municipal and industrial waste water treatment with plants. The derived effluent is of high quality enough to be discharged to coastal, surface or brackish waterways or to be reclaimed for urban irrigation. Other advantages include small footprint, easy retrofit and upgrade of old wastewater treatment plants.

Membrane Bio Reactors

-

MB units are double be system where the feed water is demin water while the treated outlet quality is very pure

(conductivity < 0.1 microsiemens / cm )

Mixed Bed

-

Southern Chemicals & Engg meets the diverse needs of municipalities through market leading technologies and processes design and build capabilities. As the percentage of the population that is served by piped water has decreased in recent years, because of rapid population growth compared to the number of connections we are constantly evaluating the opportunities presented in partnership with various industry contractors and water operators.

One such opportunity which presented itself was through a local government in Sumatera Island. The vast stretches of inland areas have little or no access to roads and this increased the transportation costs of basic necessities. With the availability clean drinking on location the government is able to cheaply satisfy a very basic need of man.

At Southern we are always looking to improve and further develop these community based solutions by working closely with the end users requirements.

MUNICIPAL